Our Brands

SAFELINE

- Established in 1992

- 100% ownership acquired by G.U.D Holdings (Pty) Ltd in 2012

- Manufacturers of high quality Original Equipment (OE), P&A and Aftermarket disc brake pads for passenger cars, light commercial vehicles and heavy duty

- Location : Johannesburg, South Africa

- Employees : 186

- Building Size : 5800m² (Site : 110 000 m²)

- Production capacity : 80 000 sets per month in a single shift

- Offers the largest range of locally manufactured disc brake pads (over 700 brake pad part numbers)

- ISO/TS 16949/2009 certified factory

- State-of-the-art in house laboratory testing facility

- The only brake pad in South Africa with both E-Mark and SABS certification

- The safest brake pad in South Africa as indicated by a AMS fade test

BREMBO

1961 was the foundation year of a company that radically transformed a mere vehicle component into a distinctive element with its own unique identity, both in terms of esthetics and performance.

In 2021, Brembo celebrates its first 60 years of history: An entrepreneurial adventure steeped in technological innovation and continuous research in design and performance, which led to a starring role in Motorsport and a constant commitment to sustainability.

In over 50 years, Brembo’s growth path has been dotted with great technological, sport and commercial successes, which have made the company a top leader in Italy and worldwide – a brand whose name is synonymous with “brakes” the world over. Its successes include the production of the first complete braking system, installed as standard on Guzzi and Laverda motorcycles in 1972; the Formula 1 supply for Ferrari in 1975; the first aluminum caliper and the first carbon discs in the 1980s. And then followed the listing on the stock exchange, the opening of new plants in all countries where the company’s clients operate, the inauguration of the Kilometro Rosso innovation district just outside Bergamo, up to the latest challenges met to respond to the current profound transformations and trends in mobility, now conceived as increasingly electric and sustainable.

QUALITY, SAFETY AND ENVIRONMENT POLICY

In its over 50 years of existence, Brembo has secured a prestigious place for itself in the automotive braking system sector.

This position can only be held through continuous innovation in products and services, maintaining the highest possible quality levels, offering competitive prices and focusing the utmost attention on safety, individual and public health and respect for the environment.

The group's Quality, Safety and Environment policy expresses Brembo's commitment to client satisfaction and ongoing improve.

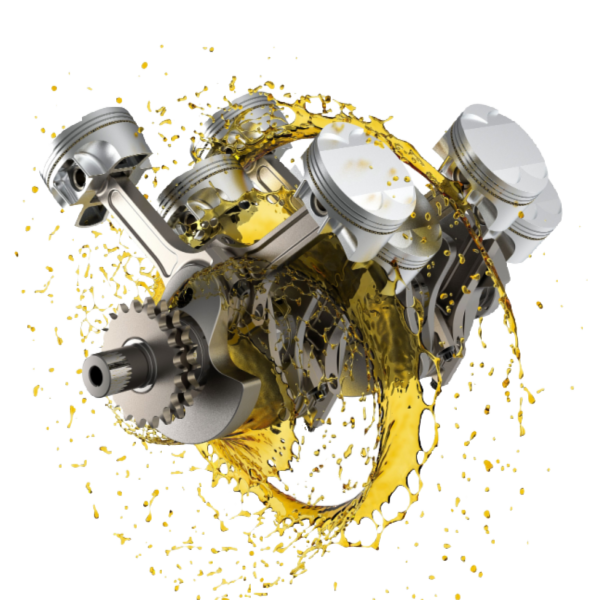

GUD

GUD Filters, South Africa’s leading automotive filter brand, manufactured its first filter in Durban in 1949. As the automotive industry evolved so the company expanded over time to become the market leader in South Africa. GUD Filters has manufacturing facilities in Durban, Pietermaritzburg and Zimbabwe and has distribution centres in Johannesburg, Cape Town, Port Elizabeth and Durban. The company’s headquarters are in Prospecton, KwaZulu Natal and it employs in excess of 1800 people.

GUD Filters has extended its success across international boundaries and currently exports to five continents. GUD places great emphasis on quality to exceed the requirements of all its market.

QUALITY

The GUD Filters quality system is regularly assessed by the South African Bureau of Standards to ISO9001/IATF16949. Our quality system, products and processes are audited regularly by OEMs to ensure their specific requirements are met.

Our dedication to quality and customer satisfaction cultivates a team ethic that extends throughout the company and includes suppliers of raw materials and services. A supplier development program encompassing quality, productivity and costing issues is vigorously pursued.

The effectiveness of the entire GUD quality system and its quality ethic has been a cornerstone of the company since its inception; thereby ensuring products consistently perform to the highest standards.

BougiCord

A little history behind the BougiCord brand:

- 1959 L’Electricfil in France patented the Wire Wound conductor concept,

... consisting of 50 turns per centimeter,

... formed onto a Ferro-magnetic core,

... resulting into today's BougiCord suppression ignition leads. - L’Electricfil® has partnerships, like BougiCord in South Africa, in Brazil, India, Malaysia, Iran, Bulgaria, Poland and South Korea.

- BougiCord is a globally approved supplier to a number of OEM’s (Original Equipment Manufacturers) like Citroen, Daewoo, Ford, GM, Honda, Hyundai, Nissan, Toyota, Renault and Volvo.

- In 1979 Mr. Mario Delfino brought the BougiCord technology to South Africa which resulted into the import and assembly of BougiCord Ignition Lead sets in South Africa.

- The transformation of the new BougiCord international logo is illustrated in where the conventional ignition lead technology was used as a base to the new electronic controlled combustion ignition technology .

- 36 years later ABES Technoseal is the only company licensed to distribute the top of the range Brand of Ignition systems in South Africa.

Ferodo

Ferodo®is the premium braking brand and one of the global leaders in both Original Equipment and aftermarket products. The brand has excelled for over 100 years in leading technical innovation. Today, Ferodo®is synonymous with excellence and a continued commitment to developing braking solutions for the future.

As a result, Ferodo®has naturally become the preferred choice in the supply of Original Equipment, and a trusted name in braking. Indeed, Ferodo®provides premium quality brake parts to the world’s leading manufacturers and the aftermarket. Of the 10 top selling vehicles in Europe, Ferodo®was factory fitted to 8 of them.

Pioneering research, innovative development, bold engineering and testing our products on the road all ensure the safety and reliability of our products. Quality is at the centre of what we do. Ferodo® has one promise: to put you in control, with products and services designed for all vehicles to help you to work efficiently, profitably and most of all, safely in all conditions. This way, wherever you drive, whatever you drive, you’re in control.

VALEO

Valeo is an automotive supplier and partner to all automakers worldwide. As a technology company, Valeo proposes innovative products and systems that contribute to the reduction of CO2 emissions and to the development of intuitive driving. In 2020, the Group generated sales of 16.4 billion euros and invested 12% of its original equipment sales in Research and Development. At December 31, 2020, Valeo had 187 plants, 20 research centers, 43 development centers and 15 distribution platforms, and employed 110,300 people in 33 countries worldwide. Valeo is listed on the Paris Stock Exchange.

LuK

The LuK Group was founded in Buehl, Germany in 1965. LuK specialises in creating high quality automotive clutches.

LuK both design and create OEM clutches for a number of car manufacturers, as well as a large range of aftermarket clutches. LuK Africa is currently the largest clutch manufacturer in South Africa. It produces clutch kits for light, medium and heavy commercial vehicles. It has a strict international quality standard to uphold and is certified under ISO 9002 and QS 9000

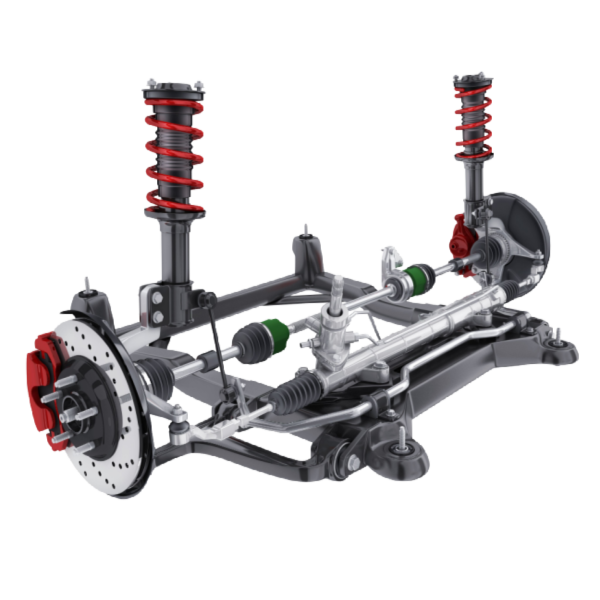

TiTAN Shocks

Good quality parts go a long way in navigating South Africa's tricky roads

Your car’s shock absorbers control the movement of its suspension when it travels over bumps or dips in the road, as well as when the driver accelerates, brakes or corners. If just one shock absorber is worn, this can lead to uneven body movement when the driver brakes or corners hard, and this lurching of the car can lead to a dangerous loss of control by the driver.

Making sure your shock absorbers are in tip-top working order is vital for a safe and comfortable ride. The Titan range of shock absorbers, now available to South African motorists through Midas stores, use high-quality components to ensure that their shock-absorbing properties are of a superior quality, and that they last longer.

Shock absorbers working at their optimum are key to your safety in the car. Not only do they absorb the excess energy generated by uneven and bumpy roads, they also ensure your car sticks to the road in windy conditions and that it has proper stopping power.

Shock absorbers also ensure your car’s stability. A faulty, poor-quality or broken shock absorber will cause a car’s wheels to bounce rapidly and continuously up and down, even on apparently smooth roads, leading to dangerously scuffed tyres. It’s recommended that you check your shock absorbers at least every 50 000 km, to prevent unnecessary wear and tear on your tyres and the various components of your car’s suspension system.

And last but by no means least, shock absorbers ensure comfort for all occupants of the car by reducing or eliminating vibratory motions due to uneven roads. With worn or poor-quality shock absorbers, all vertical energy of wheels is shifted to the frame of the vehicle, making for an unpleasant experience inside the car.

Titan shock absorbers are available in over 60 part numbers, covering some 80 percent of the cars currently in use on South African roads. They are available through Midas branches countrywide. Midas, a one-stop shop catering for the needs of any vehicle owner, provides a wide range of products from parts to accessories.

ATE

ATE branded and manufactured products have been trusted by many international car manufacturers as uncompromising on safety, with many innovations and improvements introduced throughout decades. The benefit of all the years of experience is available in the comprehensive product range supplied into the Southern African Aftermarket sector by Alfred Teves Brake Systems (Pty) Ltd, to the same quality standards as those supplied to the Original Equipment sector.

Alfred Teves Brake Systems (Pty) Ltd Quality Management System accreditations include the International Standards Organisation certifications: ISO 9001:2015 (quality management systems), ISO 14001 (environmental management) and BS OHSAS 18001: 2007. These accreditations signify the systems adhered to in every aspect of the company e.g. procurement and sourcing, accounting, manufacturing, quality control, marketing and logistics. Alfred Teves Brake Systems (Pty) Ltd is one of the first local manufacturers of brake pads to be accredited to the global ECE R90 standard, in 2009. Ongoing tests of all brake components are done to the highest quality specifications. On-site and third-party laboratories are used to ensure consistency and adherence to local as well as international regulatory requirements. Alfred Teves Brake Systems (Pty) Ltd also adheres with Original Equipment specifications. Supplementary on-vehicle testing is performed on test tracks, race tracks and in normal driving conditions.

The Alfred Teves Brake Systems (Pty) Ltd product range includes ATE branded brake pads, discs, shoes, master and wheel cylinders.

The ATE brand is renowned for its premium quality brake pads and discs. All Alfred Teves Brake Systems (Pty) Ltd brake pad formulations are locally developed to deal with the specific driving conditions in South Africa (whilst conforming to global regulatory standards). Depending on the application, replacement clips are supplied with many brake pad sets. Less commonly known is the fact that Alfred Teves Brake Systems (Pty) Ltd also manufactures brake pads for Heavy Commercial Vehicles (HCV). The friction material formulation was developed in-house to meet local operating conditions and legal requirements (passing tests for the SABS VC8053 in 2008). During 2012 the product was approved to the stringent international e-Mark specification.

Motopart

The fast growing, price sensitive markets around Southern Africa demand quality and warranted service parts. Midas has responded to these needs by offering a range of alternate product in Motopart packaging that is unequalled in terms of quality, warranty, price and stock-depth. Exhaustive research and quality testing ensures that all Motopart parts offer the consumer a peace-of-mind purchase.

NGK

NGK Spark Plugs were produced in South Africa since 1950 under the company name of Lectrolite. These spark plugs were produced under license to NGK Spark Plugs Japan. NGK Spark Plugs SA, now owned by NGK Japan, still continues to produce a range of spark plugs for the OE market, P&A market and Aftermarket. NGK Spark Plugs SA also market and distribute NGK Glow Plugs and Resistor caps.

Our Research & Development

With major R&D centres in Japan and the USA, NGKs European research and development work is based at the Technical Centre in Ratingen, Germany. This facility, established in 1990, has continuously expanded to provide technical support to the European automotive manufacturers.

The NGK Technical Centre covers an area of approx. 2,200 square metres and cost approx. 15 million Euros. It has three modern engine test rigs for endurance and application tests, together with cold-climate chambers in which engine and chassis can be cooled down to -30 degrees Celsius for analysing cold-start performance. It also has comprehensive equipment for carrying out full exhaust gas emission tests.

Today, NGK has benefited from this investment in Europe by being the OE supplier of spark plugs and or glow plugs to most vehicle manufacturers in Europe including Audi / Volkswagen, BMW, Mercedes, Jaguar, Fiat, Renault, Peugeot and Vauxhall. With worldwide legislation demanding a reduction in exhaust emission levels, NGK has developed many technologies to combat these challenges. Through its NTK brand it has been increasingly involved in the development and manufacture of oxygen sensors which have a key role to play in exhaust gas after treatment. NGK Spark Plugs is now the world’s largest producer of these useful devices.

Champion

For over 100 years, the iconic Champion® brand has been a world leader in the manufacture of spark plugs for every kind of combustion engine. From innovation in aviation technology to a tradition of motorsports dominance, the Champion® brand has been a part of product development in every type of engine. As a powerful symbol of performance driven quality, this experience and commitment has led to design enhancements that optimize the performance of every spark plug we make.

Champion® uses a proprietary approach in designing the entire line of automotive spark plugs. From the use of iridium and precious metal technologies, to F.I.S.S. resistor technology and MLR™ technology, Champion® engineers and manufactures spark plugs in an array of materials and designs, to provide a full offering of enhanced ignition and plug life as well as direct OE replacements.

Proven expertise in engineering and manufacturing OE components and subsystems for the world’s major automotive manufacturers, as well as success at the track, translates into innovative maintenance solutions for professional repair technicians, do-it-yourselfers and performance enthusiasts. We understand the importance of OE fit and form replacement parts; we know our parts adhere to the industry’s toughest standards — and to yours.

Applus Suspension

Applus is one of leading manufacturer & exporter of suspension & steering parts for the automotive aftermarket industry since 1992. Applus was focused on exporting and increased its export shares in each year to target to 100 %, exporting activities are made mainly to Europe, North & South America and Africa.

By 2008, Applus made big capacity and capability investments and today increased its capacity to 2.700.000 pcs per month together with new manufacturing plants.

With dedicated staff and over 30 years of experience of production, we are proud of giving best services.

Applus production is mainly focused on passenger cars, light and heavy commercial vehicles for European, Asian and American applications in advantage of flexible and fast service, shorter lead time, approved quality and competitively priced lines are the main features making Applus a reliable and successful long term partner.

PartQuip

For the past 36 years, Partquip’s mission has been to supply a select range of quality guaranteed auto parts, through our network of distributors, to the automotive aftermarket.

Our value proposition to our customers, typically motor spares stores, is a strong brand based on quality, sold at a reasonable price and supplied at superior levels of service.

At our core we believe that we are an extended family and we value loyalty, honesty, integrity and respect within our working environment.

Partquip was acquired by Hudaco Industries in 2014 and is accredited with ISO 9001 and B-BBEE Level 4 certification.

Our staff complement of 330 employees ensures that our branches located in Johannesburg, Durban and Cape Town operate efficiently in order to deliver exceptional service to our valued customers throughout Southern Africa.

With more than 14 000 part numbers supporting our product offering with extensive and growing ranges, we believe that we are well positioned to meet the needs of an evolving automotive aftermarket replacement parts industry.